To ensure safe and healthy working conditions of the workers, the mill conducts medical camps, health checkups, health awareness , covid protocol and safety awareness programmes. Also fire safety programmes, first aid training and crisis management programmes are conducted to equip our employees to handle any uneventful situation in all shifts inside the premises.

Since 60% of the workers are women workers working all three shifts, we have an ANTISEXUAL HARASSMENT CELL to ensure their safety and wellbeing in all shifts. We also conduct exclusive programmes to educate them on health and hygiene, family welfare , child education etc.

We maintain Policy of Nil Child Labour, No Discrimination in selecting, employing and treating all employees irrespective of religion, caste, gender, language but only value merit, hard work, sincerity and loyalty

S.A.AANANDAN MILL LIMITED believes, training plays a vital role at all levels, right from top level management to the floor level workers. We conduct meetings to cover the present mill scenario and mill productivity level, needs for good housekeeping, needs of effective work methods & their implementation and effective communication at all levels. This leads to improved production, boost in quality, worthy communication followed by savings in time, money, material and effort.

On 11.0.1.2024, First Aid Training Program was conducted for our S.A.A First Aid Team members, which was organized by Tamilnadu Apex Skill Development Centre For HealthCare, Chennaii.The Trainer addressed 30 members of our S.A.A First Aid Team and conducted class from 10 AM TO 5 PM covering vast areas like CUT INJURY, FRACTURE,FIRE INJURY, HEAD INJURY, UNCONSCIOUSNESS DUE TO SUFFOCATION, CARDIAC ARREST, HEART ATTACK, ELECTRICAL SHOCK, SNAKE BITE, BREATHING TROUBLE, FALLING FROM HEIGHT, INSECT BITE, CHEMICAL SUBSTANCE ALLERGY, OTHER INDUSTRY RELATED INJURY, CONTENTS AND USAGE OF FIRST AID BOX.

The session was very useful since practical sessions made the lessons easier to be understood by our workers.

We follow ethical and environmental practices in our production units. We do Rain Water harvesting to preserve water. We grow trees to keep campus atmosphere / ecosystem intact. We do not have effluent to treat. Smoking is strictly prohibited inside factory area and No Plastic bags of low Micron are allowed. We follow amiable policy on Health, Safety, Wellbeing and Welfare of all employees to keep them fit to carry out their duties well.

Periodical Health Check up for our Workers is a Mandatory Policy of our company. In addition to this, we regularly conduct PULMONARY and AUDIOMETRIC tests

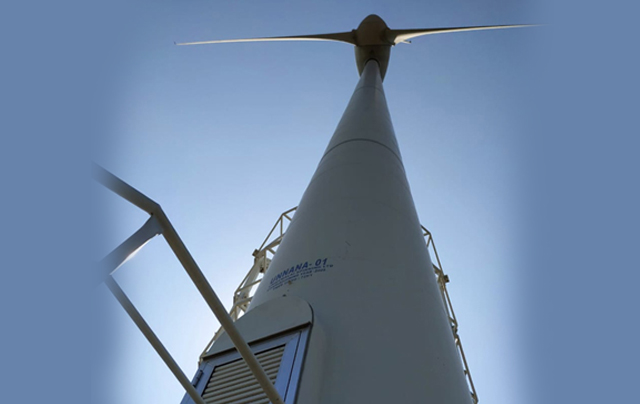

In the year 2005, we installed ENERCON WINDMILL of capacity 330KW in the outskirts of Tharapuram in a field of area 1acre. Our WINDMILL generates 4.75 lakh units /year. Apart from this, we also outsource WIND POWER for running the plant. In total, WIND POWER contributes to 66% of the total power consumed in our plant.

Since we are aware that renewable source of energy is the best way of sourcing power, we plan and propose to go for solar Power in the year 2024-25

RAINWATER HARVESTING

We have a well which is 46 ft deep. Actually it was a salty water well whose TDS was 2010 as on 05.05.2013.We erected the 6" dia pipes connecting all weathering course and drained every single drop of rainwater collected in terrace into well, we were surprised to see gradual decrease in TDS level of the well water which was recorded as 921 as on 30.10.2020.We Continuously keep track on the condition of well water which we found to have TDS level 145 and PH level 6.6 as on 2.1.24 Now that the rain water drained in the well has changed the quality of water, we save on the expenses spent on cleaning Humidification plants, Humifog, Yarn Conditioning Plants and RO plants. In addition to that our well water level has also started increasing. Now, we don't outsource water for any of our needs.

RECYCLING SEWAGE WATER

With the view of going green even in sewage water / drainage water system, we started using bioenzyme in all our Septic tanks from 2017. These bioenzymes decomposed all sewage waste and purified the sewage water which was also tested and found to be pure enough to water our plants. So we continued this practice and also used only herbal cleaning agents for cleaning our toilets. But after Corona pandemic, the supplier stopped supplying the bioenzyme and hence we could not continue with it.

SOLAR STREET LIGHTS

Moreover, as a beginning stage of going for solar power, we begun with 52 nos of Solar Street Lights that we installed in the year 2014. We don't use power at all for lighting up the walkable area in mill premises and that saves atleast 120 units of power in a day.